Carbide Processors

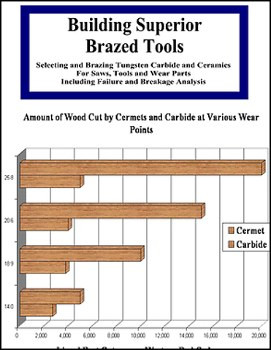

Building Superior Brazed Tools 2008

$71.40

- SKU:

- 981-BK01

- Availability:

- This item is made to order and typically ships within 1-2 weeks. If an unexpected delay occurs, we will contact you as quickly as possible.

- Shipping:

- Calculated at Checkout

- Tool:

- Book

- US Made:

- 0

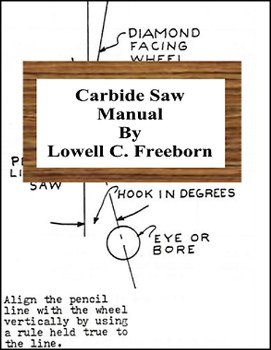

By Thomas Walz, President Carbide Procesors, Inc Published: February 2008 Paperback: 229 pages , 422 illustrations, 77 chapters, Binding: Wire.

This book was written as a practical working guide for using the new technologies. It is based on twenty six years of helping people building better tools. Building Superior Brazed Tools 2008 gives great, in depth material on selecting the right materials and using them. It is for those that wish to build the very best with the current and next generation technologies.

Topics covered in the book:

| Hardwood Sawmill Downtime Costs | Brazing Gases | |

| Superiority of Brazed Tools over Mechanically Held Tools | Brazing Process Overview | |

| Brazing and Welding - Important Differences | Brazing Tungsten Carbide | |

| Tool Tipping Materials | Brazing Tungsten Carbide for the First Time | |

| Tool Tipping Material Comparisons | Braze Technique for Testing and Training | |

| Measuring Material Properties | Cleaning Steel Before Brazing | |

| Hardness Testing | Cleaning Saw Blades | |

| Hardness Conversion Scale | Brazing To Laser Cut Steel | |

| Tool Steels | Trying To Clean By Burning With A Torch | |

| Talonite | How Fluxing Affects Brazing | |

| Stellite and Other Metal Alloy Tipping | Calculate The Amount Of Braze Alloy To Use | |

| Tungsten Carbide Explanation and Manufacturing | Braze Joint Thickness | |

| Tungsten Carbide Grades | Pretinning | |

| Cross Referencing Carbide by Grade | Temperature Control and Problems | |

| Properties of Tungsten Carbide | Heat Stress in Brazing | |

| Carbide Surface Treatments | Times | |

| Why Good Carbide Is Important | Brazing Carbide in a Notch - Three Methods | |

| Considerations In Tungsten Carbide Selection | Advanced Brazer Training | |

| Basic Saw Tip Ordering Information | Brazing Standards for Tungsten Carbide in Automatic Systems | |

| Common Carbide Defects (Internal and External) | Brazing Thin Materials | |

| Crack Initiation and Propagation | Wizzeroo High Temperature Tool | |

| Quality Specifications for Carbide Saw Tips | Welding Tungsten Carbide | |

| Carbide Specification Checklist | Telling Braze Quality - Examining The Finished Joints | |

| Carbide Suppliers Questionnaire | Fillets | |

| How Carbide 'Wears Out' | Microscopic Examination of Tools | |

| Wetting Tests | Proscope Analysis of a 10" saw blade | |

| Chipping Carbide | Simple Carbide and Braze Joint Strength Tests | |

| Cermets | Grinding and Honing Tungsten Carbide | |

| Advanced Materials | Coolant Cleanliness | |

| Cermet II - Advanced Grades | Why Coolant Doesnt Last Forever | |

| Making Cermet II Materials | Filtering coolant | |

| Braze Alloys (Silver Solders) | Grinder Coolant Analysis Sawmill | |

| Brazing with Trimetal Shims | Clean Coolant Makes Money | |

| Trimetal Shims And Hi Impact Braze Alloy | Coolant Testing Kit | |

| Cadmium Free Alloys | Measuring Grinding Accuracy | |

| Flux | Brazing Tungsten Carbide - Health and Safety | |

| Gas Flux | Grinding Tungsten Carbide - Health and Safety |

![]() WARNING: Cancer and Reproductive Harm—www.P65Warnings.ca.gov

WARNING: Cancer and Reproductive Harm—www.P65Warnings.ca.gov

Our customer's satisfaction is our top priority! Please let us know if you are unhappy with a purchase for any reason and we will do whatever we can to make it right for you. This includes seeking a full manufacturer's refund based on their individual warranty policies (if a product is defective) or working with you to coordinate a return or exchange for unused products that do not meet your needs.